The project under the MIC responsibility and part of its plan to develop local production capabilities with the assistance of German specialized company named EMT.

Case Study

Luna Project Al-Kharj

The project under the MIC responsibility and part of its plan to develop local production capabilities with the assistance of German specialized company named EMT.

Scope of project:

The scope of project is to produce parts for military use. Which its construction consists of Main Buildings (factory & Training Center) and Service Buildings (Truck Wash & Service Block) with Security Gates (Main & Secondary). With total build up area of 70263 m²

Project's brief

Client: MIC Corporation

Main Contractor: Arabian Gulf Co.

Consultant: DORSCH International Consultants / KHATIB & ALAMI

Location: Al-Kharj, KSA

Scope of work: Total electro-mechanical work

Project duration: 2015 – 2018

Contract Value: 18,000,000$

Significant Installation:

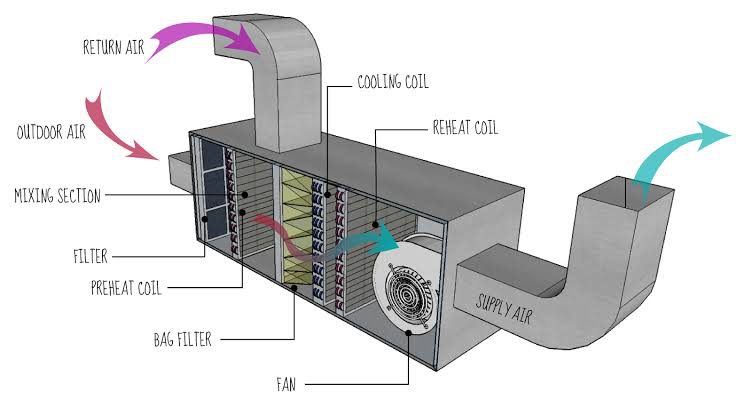

Mechanical

- Installation of Chilled water system to obtain cooling for the main buildings with total capacity of 788 TR

- Installing of Crack Units to obtain Cooling in IT & Control Rooms.

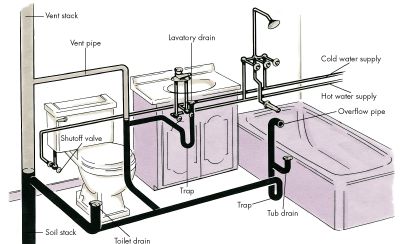

- Installing of Domestic Water Pumps to service all Wet Area of the Project.

- Installing of Drinking Water Pumps to service Kitchens & Cafeterias Areas in Main Buildings.

- Installing of Truck Wash Pumps.

- Installing of Irrigation Pumps for serving all external Landscape.

- Installing of all Toilet Fixtures & Accessories of all Buildings (Main / Secondary & Service building).

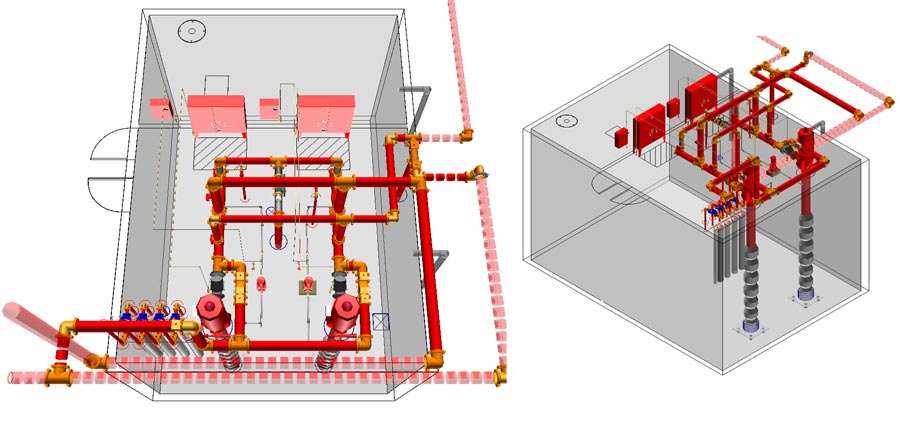

- Installing of Fire Pumps Sets (Diesel / Electric & jockey) for protecting Main Building with total capacity of 1000 GPM with a head of 13.5 Bar

- Installing of Novec System & FM-200 for IT & Control Rooms in Main Buildings.

- Installing of Automatic Fire Extinguisher in Generator Room.

- Installing of Fire Hydrant for the External Area.

Electrical

- Installation of Metered RMU SM6, 13.8KV, 630A, 3-Way (1xDM1-A + 2xIM) MRMU as per SEC Standard.

- Installation of Medium Voltage Switchgear SM6, 13.8KV, 630A, 21kA/1Sec 7-Column (6xDM1-A + 1xCM).

- Installation Cast Resin Transformer TRIHAL Type 1600KVA (3No.) & 1000KVA (1 No.).

- Installation of Prime Generator 2250 KW, 60Hz, 400V.

- Installation of MDB’s (Prisma Plus P) & SMDB’s (Prisma Plus P) & MSP’s (Prisma Plus P) & ATS’s & LP’s (Disbo Raw) & PP’s (Disbo Raw)

- Installation of Low Voltage & Medium Voltage Cable XLPE/PVC

- Installation of Duct Bank – Underground.

- Installation of Low Voltage Feeder Busway.

- Installation of Lighting Fixture (Interior & Exterior)

- Installation of Wiring Devices.

- Installation of Disconnect Switch.

- Installation of Grounding System & Lightning Protection system.

- Installation of Uninterruptible power supply.

- Installation of CCTV (IP) Security system

- Installation of Fire Alarm & Emergency Communication System.

- Installation of BMS (Building management system).

- Installation of Audio Visual system.

- Installation Data and Voice Cabling system, Communications Backbone Cabling, Communications Equipment Room Fittings

- Installation of Access Control system.

- Installation of Intrusion system.

Downloads

Projects Estimation

Download pdf details about the project estimation

Drawings and layouts

Download the drawings and layouts of the project

Download file

Project Challenges

See the challenges and complexities we faced during the completion of the project

Project Gallery

Our Trusted Clients